Table of Contents

Published on: October 31, 2023

Searching for methods to cut down defects and costs in your auto production process? ecubix has the perfect answer! Our innovative digital checklist can supercharge your production process. Revolutionize your automotive manufacturing with ecubix – get ready!

The Automotive Parts To be Tested

Discover how ecubix’s eChecklist can help you manage your automotive parts’ data and testing reports. This innovative solution simplifies the testing process and lowers the production costs and defects.

With eChecklist, you can ensure that your products meet the quality standards. It covers various components such as suspension systems, braking systems, and fuel systems. You can also monitor the testing progress and verify that all parts are inspected thoroughly. Don’t miss this opportunity to improve your manufacturing process with ecubix’s eChecklist. Reduce defects and enhance product quality today!

Unicorns on Harleys? That’s as rare as failing to meet quality requirements and standards.

eChecklist For Quality Requirements and Standards

ecubix has developed a revolutionary digital checklist for the automotive industry, that meets all quality requirements and standards. Its automation reduces errors, allowing manufacturers to spot and amend any defects quickly.

The best part? It’s customizable, so it can fit various regulatory requirements and international standards. Plus, it collects, analyses and reports data in real-time, giving manufacturers a new insight into their production process.

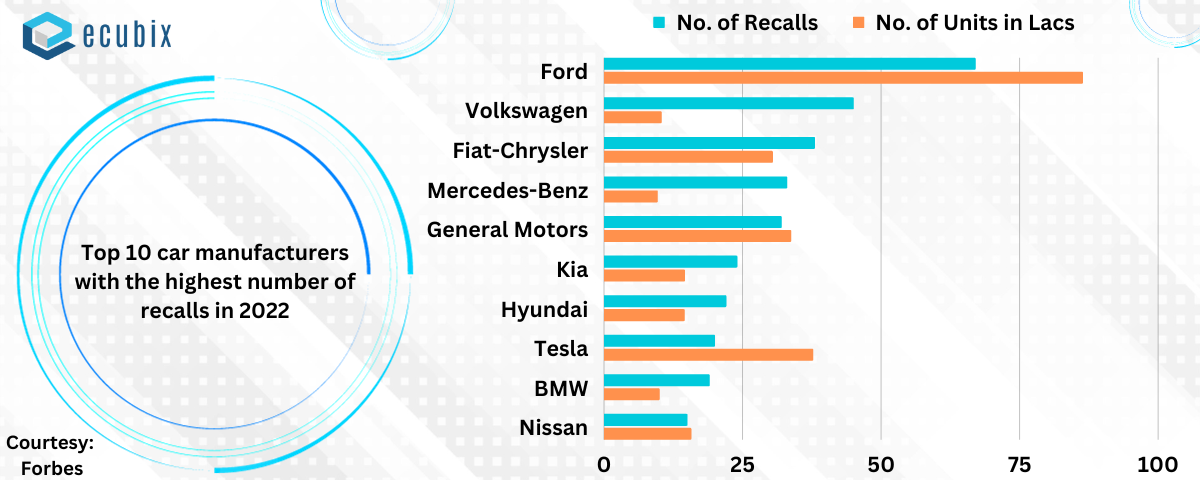

By implementing ecubix’s eChecklist, companies can reduce defects and costs related to rework or recalls. It also improves product quality, customer satisfaction and profitability.

Lead the way in the automotive industry. Be part of the solution revolution and implement ecubix’s eChecklist today to streamline and optimize the manufacturing, sales, service and maintenance processes.

Major Defects that The Consumer will Notice or Not Notice

ecubix’s eChecklist helps you identify defect issues faster, lowering the chances of delivering faulty vehicles and saving production costs. Unlike the old manual inspection with paperwork methods that were slow and unreliable, ecubix’s eChecklist uses digital technology to spot major defects easily so you can fix them ASAP.

ecubix’s eChecklist has revolutionised the auto industry. It’s much faster and more accurate. However, even the best checklist can’t save you from a vehicle that spontaneously combusts. But ecubix is here to help!

Critical defects that pose a safety hazard

Potential risks that can harm individuals in the automotive industry arise from critical defects that present a safety hazard. If not addressed, these defects can cause accidents and injuries.

This checklist focuses on safety hazards in automotive manufacturing:

- Faulty braking systems can lead to accidents and loss of control.

- Steering issues can make manoeuvring difficult and increase the risk of collisions.

- Electrical system malfunctions can cause failures of crucial components like airbags and lights.

- Structural weaknesses can weaken the vehicle’s integrity and increase the chances of injuries.

- Insufficient or non-functional safety features like seat belts, airbags, and warning systems can be dangerous.

It is important to consider these aspects while assessing automotive production processes. ecubix’s innovative solution automates checks and ensures adherence to safety standards. This digital checklist provides real-time insights into potential hazards, enabling proactive interventions. So, manufacturers can minimize risks and reduce costs associated with recalls or product liability claims.

The Proper Function of Each Module

Introducing ecubix’s innovative digital checklist for automotive manufacturing! This tool helps to reduce defects and costs throughout the production process.

Automated data collection and analysis make it easy to track each part’s performance and identify any potential concerns. This allows for faster decision-making and timely adjustments to optimize production efficiency.

This idea was inspired by a massive recall caused by defective parts. ecubix developed this eChecklist as a solution to reduce defects and costs.

ecubix: revolutionizing the automotive industry with their eChecklist! Saving costs and reducing defects has never been so cutting-edge!

Why ecubix is The Top Choice for Automotive Industry for eChecklist Solutions?

ecubix is shaking up the auto industry with its innovative end-to-end eChecklist solutions. Their innovative digitized checklist technology has made them a pioneer in revolutionizing manufacturing. This provides real-time tracking, plus advanced analytics, so automotive firms and ventures can cut down on mistakes and costs.

Their special strength is the ability to craft custom digital checklists that are tailored to the auto sector. With their advanced tech, ecubix makes sure each step meets top-notch quality standards. Manual errors are gone, and procedures are streamlined so any issues can be identified and fixed quickly, increasing efficiency and cutting down on rework and traditional paperwork.

ecubix also offers features like comprehensive reporting and data analysis, so companies can get valuable insights into how their production lines are working. This helps them make proactive decisions, reducing risks and increasing productivity. Plus, it has a user-friendly interface, so it can be adopted without interfering with existing operations.

ecubix provides an end-to-end solution approach, covering everything from assembly lines and quality control to supply chain management and inventory tracking. This all-inclusive strategy sets them apart as the go-to for optimizing automotive operations.

FAQs

1. What is the innovative digital checklist by ecubix for automotive manufacturing?

The innovative eChecklist by ecubix is a comprehensive tool designed specifically for the automotive manufacturing industry. It helps manufacturers streamline their production process, reduce defects, and lower costs.

2. How does the eChecklist reduce defects in the production process?

The digital checklist ensures that all necessary quality checks and inspections are conducted at each stage of the production process. This helps identify and rectify any defects or issues early on, preventing them from escalating and reducing the overall number of defects in the final product.

3. What features does the digital checklist offer?

The digital checklist offers features such as real-time data capture, automated reminders for pending tasks, customizable checklists based on specific manufacturing requirements, integration with existing systems, and comprehensive reporting and analytics.

4. How does the digital checklist help in reducing costs?

By minimizing defects and enhancing efficiency in the production process, the digital checklist helps reduce the number of product recalls, rework, and warranty claims. This leads to significant cost savings for automotive manufacturers.

5. Is the eChecklist easy to implement?

Yes, the eChecklist is designed to be user-friendly and easy to implement. ecubix provides comprehensive support and training to ensure a smooth integration of the checklist into the manufacturing process.

6. Can the digital checklist be customized for specific manufacturing requirements?

Yes, the digital checklist can be tailored to meet the specific needs of different automotive manufacturers. It can be easily customized to include industry-specific quality checks, inspection criteria, and other relevant parameters.