In today’s fast-paced manufacturing industry, success hinges upon efficient processes and streamlined operations. 80% of the global workforce falls under the “frontline” category, encompassing individuals directly involved in production, customer service, and other operational roles. 70% of frontline managers desire an updated manufacturing process with the latest technologies to increase efficiency in a shorter timeline.

To stay competitive, companies must embrace innovative solutions that empower their frontline workers and boost productivity. Enter eLogbooks – the game-changer for manufacturing. Studies reveal that manual data collection and paper-based recordkeeping can lead to significant inefficiencies, with errors costing manufacturers up to 8% of their revenue annually.

As frontline personnel are the backbone of any manufacturing operation, providing them with real-time data access and accurate record-keeping are critical. And eLogbooks provide exactly that! By digitalizing the data collection and entry process, manufacturers can improve frontline access to critical data and achieve greater transparency and collaboration.

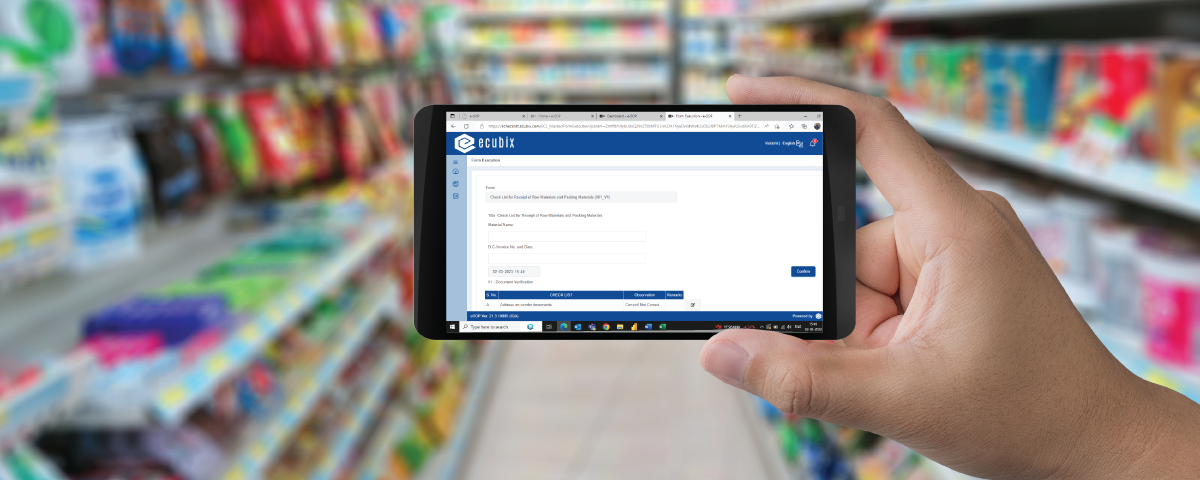

eLogbooks have revolutionized the manufacturing industry by streamlining processes for frontline success. By replacing traditional logbooks with digital checklists, manufacturers can now achieve higher efficiency and accuracy in their operations.

The Role of eLogbooks in Improving Production Processes and Quality Control

(1) Enhanced data collection and accessibility: eLogbooks facilitate the digital capture of critical production data, including machine performance, process parameters, and quality control checks. This eliminates the need for paper-based records and allows for real-time access to information, improving transparency and traceability.

(2) Streamlined communication and collaboration: eLogbooks provide a centralized platform for teams to share information, updates, and observations. This fosters better communication and collaboration between production personnel, quality control specialists, and management, leading to faster issue resolution and improved coordination.

(3) Standardized procedures and improved compliance: eLogbooks can be programmed with specific workflows and checklists, ensuring that staff follows standardized procedures for every task. This reduces the risk of human error and helps maintain consistent quality, meeting regulatory compliance requirements.

(4) Real-time data analysis and process optimization: eLogbooks enable the collection of vast amounts of production data over time. This data can be analyzed using various tools to identify trends, bottlenecks, and areas for improvement. This allows manufacturers to optimize processes, reduce waste, and enhance overall efficiency.

(5) Improved decision-making and proactive maintenance: eLogbooks provide valuable insights into equipment health and performance. By analyzing trends in equipment data, companies can predict potential failures and schedule preventative maintenance, minimizing downtime and production disruptions.

Benefits of Using eLogbooks in Manufacturing

(1) Enhanced compliance: eLogbooks facilitate adherence to regulatory requirements by providing secure, tamper-proof records of all production activities. This simplifies audits and reduces the risk of non-compliance penalties.

(2) Improved data integrity and traceability: eLogbooks eliminate the potential for errors and inconsistencies associated with paper-based records. They ensure complete traceability of all actions and events throughout the production process, allowing for easier identification of root causes and corrective actions.

(3) Increased efficiency and productivity: eLogbooks streamline data collection, reporting, and communication, freeing up valuable time for production personnel. This allows them to focus on core tasks, leading to increased efficiency and overall productivity.

(4) Reduced paper usage and environmental impact: Replacing paper logbooks with eLogbooks significantly reduces paper consumption, contributing to a more sustainable manufacturing operation.

(5) Cost savings: While an initial investment might be required, eLogbooks can deliver long-term cost savings by reducing paper costs, minimizing administrative burdens, and improving process efficiency.

(6) Improved decision-making and data-driven insights: eLogbooks provide valuable data that can be analyzed to identify trends, optimize processes, and make informed decisions based on real-time insights.

How eLogbooks Enhance Communication and Collaboration on the Frontline?

(1) Centralized platform for information sharing: eLogbooks function as a central repository for all production-related information, including notes, observations, and shift handover reports. This eliminates the need for relying on verbal communication or scattered paper records, ensuring everyone has access to the latest information.

(2) Improved transparency and accountability: eLogbooks provide a clear audit trail of all actions and decisions taken on the frontline. This fosters transparency and accountability, encouraging continuous improvement and shared ownership of production processes.

(3) Real-time communication and issue resolution: eLogbooks enable real-time communication between frontline personnel, supervisors, and other stakeholders. This facilitates faster issue identification and problem-solving, minimizing downtime and production delays.

(4) Enhanced knowledge sharing and learning: eLogbooks can be used to capture and share best practices, troubleshoot problems, and document lessons learned. This fosters a collaborative learning environment where frontline personnel can continuously improve their skills and knowledge.

(5) Streamlined reporting and documentation: eLogbooks automate data collection and reporting, reducing the time and effort required for manual paperwork. This allows frontline personnel to focus on their core tasks and eliminates the risk of errors associated with manual data entry.

The Impact of eLogbooks on Compliance Management and Traceability in Manufacturing

Manufacturing operations are subject to a multitude of regulations governing various aspects, such as quality control, safety, and environmental impact. eLogbooks play a crucial role in ensuring compliance and maintaining robust traceability throughout the production process:

(1) Enhanced recordkeeping and audit trails: eLogbooks provide a centralized, secure, and tamper-proof repository for all production records, including process parameters, equipment performance logs, and quality control checks. This eliminates the need for paper-based documentation, simplifying audits and reducing the risk of non-compliance penalties.

(2) Improved data integrity and accountability: eLogbooks prevent unauthorized data manipulation and ensure the integrity of all recorded information. This fosters accountability among personnel and allows for easier identification of any deviations from standard procedures.

(3) Streamlined reporting and visibility: eLogbooks facilitate the generation of comprehensive reports that meet regulatory requirements. This improves transparency and provides regulators with clear visibility into the manufacturing process.

(4) Efficient identification and resolution of non-conformances: eLogbooks enable real-time monitoring of production data and identification of potential non-conformances. This allows for immediate corrective actions to be taken, minimizing the impact on product quality and regulatory compliance.

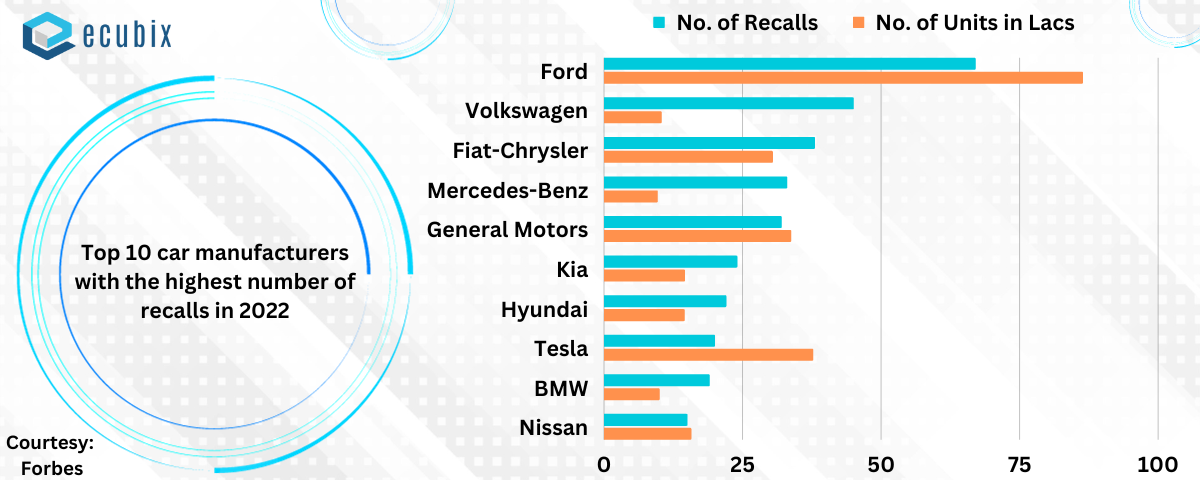

(5) Facilitates product recalls and traceability: In case of product recalls, eLogbooks enable efficient tracing of affected products back to their origin within the production process. This allows for targeted recalls, minimizing disruption and safeguarding consumer safety.

Empower Your Frontline Workers with eLogbooks for Enhanced Efficiency and Success in Manufacturing Operations

Emowering your frontline workers with eLogbooks is not just about replacing paper records; it’s about fostering a culture of collaboration, data-driven decision-making, and continuous improvement. This, in turn, paves the way for enhanced efficiency, improved quality, and ultimately, the success of your manufacturing operations.