In today’s interconnected global economy, businesses face a multitude of challenges that threaten their brand integrity and profitability. Among these, the grey market – also known as the parallel market – stands out as a persistent and growing concern. This market, where genuine products are sold through unauthorized channels, poses significant risks to brands, from undermining pricing strategies to eroding customer trust. The rise of grey market activities necessitates the adoption of advanced technologies, such as innovative track and trace systems, to protect brands and ensure their long-term success.

Data from the World Customs Organization (WCO) shows that the number of grey market cases reported by companies increased by 38% between 2020 and 2022. This surge is attributed to the increasing accessibility of online marketplaces, where unauthorized sellers can easily reach consumers across borders, often at the expense of legitimate retailers.

Common Industries Affected by Grey Market Activities

Certain industries are more vulnerable to grey market activities than others, primarily due to the high value of their products and the complexity of their supply chains. Some of the most commonly affected industries include:

(1) Electronics: High consumer demand for electronics, coupled with frequent product launches, makes this industry particularly susceptible to grey market activities. A report by the International Data Corporation (IDC) found that up to 10% of all electronics sold globally are through grey market channels.

(2) Pharmaceuticals: The pharmaceutical industry is heavily regulated, but grey market activities still thrive, especially in regions where there are disparities in drug prices. According to the Pharmaceutical Security Institute, 12% of global pharmaceutical sales in 2021 were estimated to be from grey market sources.

(3) Luxury Goods: The luxury goods market is another major target for grey market sellers. Brands like Louis Vuitton and Rolex have reported significant losses due to grey market sales, which are often driven by price differentials between regions. The luxury market research firm Bain & Company estimated that grey market sales accounted for 20-30% of global luxury goods sales in 2022.

(4) Automotive: The automotive industry also faces challenges from the grey market, particularly with spare parts and accessories. The Motor & Equipment Manufacturers Association (MEMA) reported that grey market sales of automotive parts in the U.S. alone amounted to $12 billion annually.

Introduction to Advanced Track and Trace Technology as a Solution

One of the most effective technologies for brand protection is advanced track and trace systems. Track and trace technology allows businesses to monitor the entire lifecycle of a product, from manufacturing through distribution to the end consumer. This technology provides real-time visibility and control over the supply chain, ensuring that products are not diverted to unauthorized markets.

A report by Deloitte highlights that 79% of companies that implemented advanced supply chain technologies experienced a significant reduction in grey market activities and counterfeiting. This demonstrates the critical role that technology plays in protecting brand reputation in an era where supply chain complexity and global reach can expose businesses to greater risks.

According to a report by Grand View Research, the global track and trace solutions market was valued at $2.4 billion in 2022 and is expected to grow at a compound annual growth rate (CAGR) of 17.8% from 2023 to 2030. This growth is driven by increasing regulatory requirements, rising demand for supply chain transparency, and the need to combat counterfeit goods.

Track and trace technology works by assigning unique identifiers – such as barcodes, QR codes, or RFID tags to each product. These identifiers are scanned at various points along the supply chain, creating a digital trail that brands can monitor in real-time. If a product is diverted to an unauthorized channel or tampered with, the system can immediately alert the brand, enabling them to take swift action.

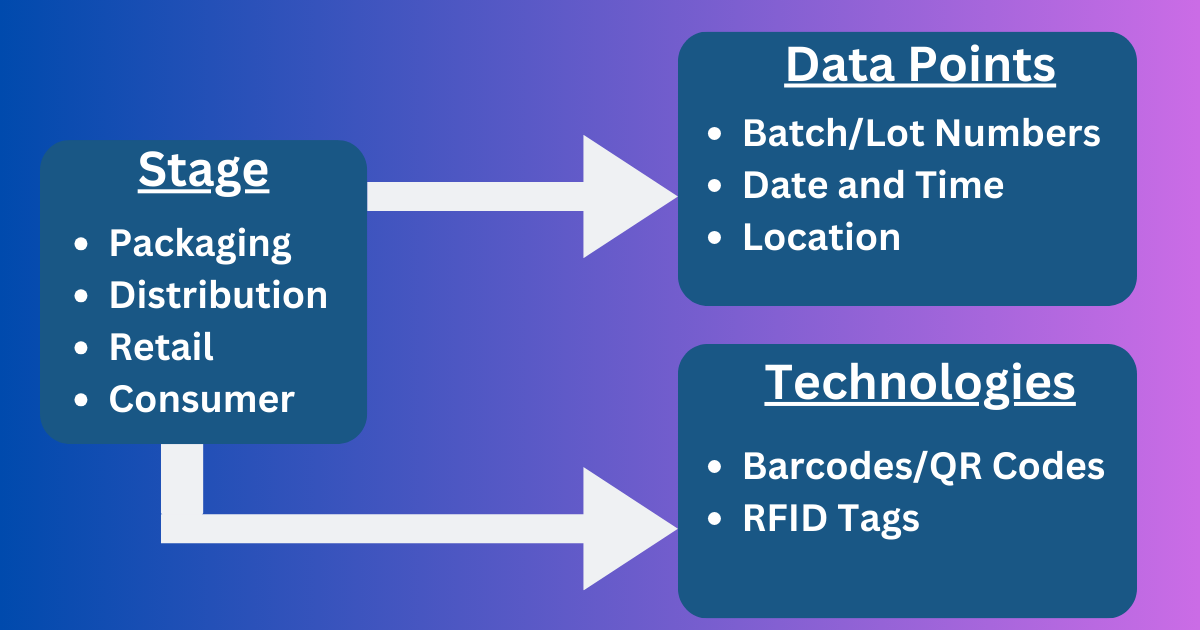

How Track and Trace Technology Works? From Packaging to End-User

The track and trace process typically begins at the packaging stage, where each product or batch is assigned a unique identifier. This identifier is linked to information such as the product’s origin, manufacturing date, batch number, and destination. As the product moves through the supply chain, it is scanned at various checkpoints – such as distribution centers, warehouses, and retail outlets – updating its status and location in the system.

(1) Packaging: The first step in the track and trace process involves assigning a unique identifier to each product or batch during packaging. For example, in the pharmaceutical industry, each medicine bottle or packet is often labeled with a 2D barcode or RFID tag that contains detailed information about the product.

(2) Distribution: As the product is distributed to various locations, it is scanned at each checkpoint. This data is recorded and stored in a centralized database, allowing businesses to monitor the product’s progress in real-time. This stage is crucial for detecting any discrepancies, such as products being diverted to unauthorized locations.

(3) Warehousing: Upon arrival at a warehouse, the products are again scanned to ensure they have reached the correct destination. Warehouses often employ automated systems to track and manage inventory, ensuring that only authorized personnel handle the goods.

(4) Retail: Before reaching the consumer, products are scanned at retail outlets. This final scan ensures that the product has arrived at the correct location and is ready for sale. Retailers can also use this data to manage stock levels and ensure product availability.

(5) End-User: Finally, when the product reaches the end-user, the unique identifier can be used to verify its authenticity. Consumers can scan QR codes or barcodes using a smartphone app, providing them with information about the product’s origin and journey through the supply chain. This step is particularly important in industries such as pharmaceuticals and luxury goods, where product authenticity is critical.

Benefits of Implementing Track and Trace

(1) Real-Time Visibility into the Supply Chain

One of the most significant benefits of track and trace technology is the real-time visibility it provides throughout the supply chain. This visibility allows businesses to monitor the movement of products at every stage, from manufacturing to the end consumer, ensuring that each item is where it should be at any given time.

Moreover, real-time data enables companies to make more informed decisions, optimizing their supply chain processes. For instance, a report by the Aberdeen Group found that organizations with real-time supply chain visibility achieved a 15% reduction in inventory levels and a 20% improvement in order accuracy. These improvements translate to cost savings and better service levels for customers.

(2) Ensuring Product Authenticity and Preventing Counterfeiting

Counterfeiting is a growing concern for businesses across various industries, leading to significant revenue losses and damage to brand reputation. Track and trace technology plays a crucial role in combating this issue by ensuring product authenticity at every stage of the supply chain.

According to the World Economic Forum, global trade in counterfeit goods is estimated to be worth $4.5 trillion annually, with industries such as pharmaceuticals, electronics, and luxury goods being particularly vulnerable. By implementing track and trace systems, businesses can assign unique identifiers to each product, making it possible to verify its authenticity at any point in the supply chain.

A study by the International Chamber of Commerce (ICC) revealed that companies using track and trace technology to combat counterfeiting experienced a 50% reduction in counterfeit incidents. This not only protects revenue but also helps maintain consumer trust. For example, in the pharmaceutical industry, where counterfeit drugs can have life-threatening consequences, track and trace systems are essential for complying with regulations like the Drug Supply Chain Security Act (DSCSA) in the United States.

(3) Improved Efficiency and Reduced Operational Costs

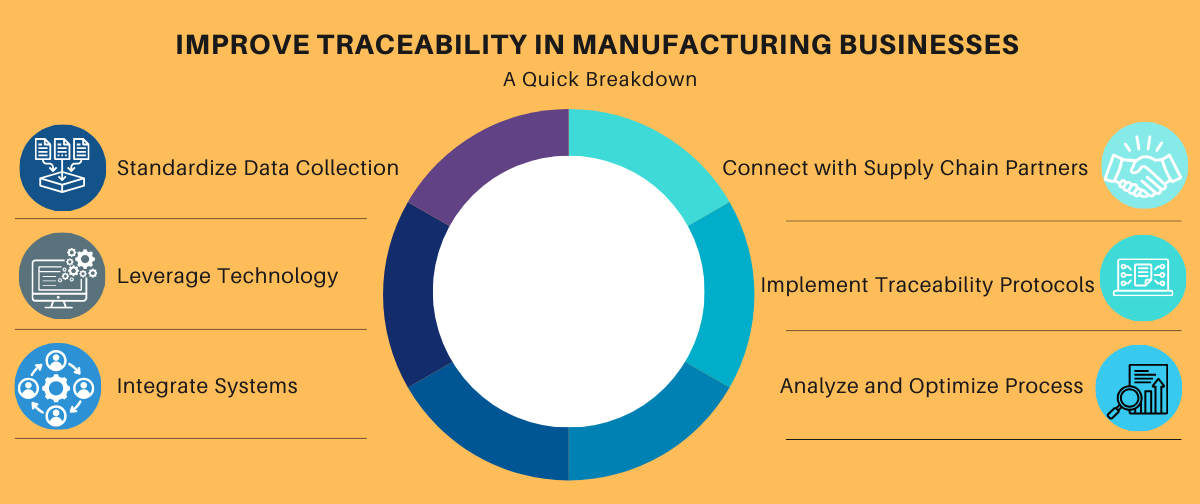

Implementing track and trace technology can also lead to significant improvements in supply chain efficiency and reductions in operational costs. By automating the tracking process and providing real-time data, businesses can streamline their operations, reduce manual errors, and optimize inventory management.

A study by Deloitte found that companies using advanced track and trace systems achieved a 25% reduction in supply chain costs. These savings were primarily due to improved inventory management, reduced need for safety stock, and decreased instances of product obsolescence or expiration. For example, in the food and beverage industry, where products often have limited shelf lives, track and trace technology can help ensure that items are sold before they expire, reducing waste and associated costs.

Integrating Anti-Counterfeit Features in Track and Trace

Serialization, QR codes, and RFID (Radio Frequency Identification) technology are among the most effective tools in the fight against counterfeiting. These technologies are integrated into track and trace systems to ensure the authenticity of products as they move through the supply chain.

Serialization involves assigning a unique serial number to each product or batch, which is then tracked throughout the supply chain. This unique identifier makes it possible to verify the authenticity of each item at any point, ensuring that counterfeit goods are easily identifiable. According to a study by GS1, the global standard for business communication, the use of serialization in the pharmaceutical industry has reduced the incidence of counterfeit drugs by 48% in markets where it is mandated.

QR Codes are another effective tool, allowing consumers and supply chain partners to quickly access product information by scanning the code with a smartphone. This not only helps verify authenticity but also provides additional information about the product’s origin, ingredients, and handling instructions. A 2023 survey by Statista found that 67% of consumers in the United States have used QR codes to verify product authenticity, with 85% of them finding it to be a reliable method.

RFID Technology uses radio waves to track products throughout the supply chain. Each product is tagged with an RFID chip that contains specific information about the item. These chips can be scanned remotely, allowing for real-time tracking and monitoring. A report by Allied Market Research forecasts that the global RFID market will reach $40.5 billion by 2030, driven by its widespread adoption of anti-counterfeiting measures across industries such as retail, healthcare, and electronics.

Ready to Tackle Grey Market and Anti-Counterfeit Challenges?

Advanced track and trace technology offers a robust solution against the grey market and anti-counterfeiting by providing real-time visibility into the supply chain, preventing unauthorized diversions and ensuring product authenticity. Additionally, educating consumers and building transparent supply chains further enhances brand protection and consumer confidence. Implementing these strategies is essential for safeguarding your brand against the risks of the grey market and anti-counterfeiting.